Pressure Release Valve are used the discharge the high pressure in the cement silo. Those valves start to run when the pressure value reaches the pre-set pressure limit value.

Those valves are the equipments that keeps the pressure in the cement silo in desired values and prevent the cement silo filter from breaking down.

The cement is transferred from silobus to cement silo with high pressure. In case there is no cement in the silobus, only the air is transferred into the cement silo and thus there occures high pressure in the cement silo. At this moment if Pressure Release Valve do not start to run , the cement silo and the cement silo filter can be damaged seriously.

Fluidizing system involves distribution pipe and nozzles. Distribution pipe is assembled into cement silo by fixing parts that are pre-assembled in to the cement silo. This system makes the cement in the cement silo bloated out. The advantage of this system does not harm the metal structure of the cement silo like the systems with vibrators do.

Silo Top Filter is a cylindrically shaped dust collector for venting of pneumatically filled silos. The stainless steel body contains vertically mounted, Silo Top Filter filter elements. The air jet cleaning system is integrated in the hinged weather protection cover. Silo Top Filter has Compact 800mm (30in) diameter 304 stainless steel body with bottom flange, 24.5m2 (264 sq ft) filter surface, High filtration efficiency due to Low dust emission level due to B.I.A.-certified filter media, Maintenance-free air jet cleaning unit integrated inside weather protection cover.

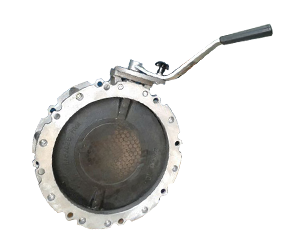

A butterfly valve is a valve which can be used for isolating or regulating flow. The closing mechanism takes the form of a disk. Operation is similar to that of a ball valve, which allows for quick shut off. Butterfly valves are generally favored because they are lower in cost to other valve designs as well as being lighter in weight, meaning less support is required. The disc is positioned in the center of the pipe, passing through the disc is a rod connected to an actuator on the outside of the valve. Rotating the actuator turns the disc either parallel or perpendicular to the flow. Unlike a ball valve, the disc is always present within the flow, therefore a pressure drop is always induced in the flow, regardless of valve position.

Minimum - Maximum level indicator is a limit value indicator that is used to check the cement filling volume in the cement silo. This indicator is used to determine the maximum and minumum level of the cement in the cement silo by using of rotary motion.

When the cement amount in the cement silo reaches the turning pedal of the indicator, there occures a signal shows that the cement amount has reached to that level. When the cement amount goes down under the indicator level, the turning pedal starts to move again and thus the other units of the system start to move too. Minimum - Maximum level indicators usually are used to determine filling level of the material which has 0,5-2,0 ton/mł density in the cement silo and mostly they are assembled on bottom and top parts of the cement silo.

The Screw Conveyor are used to transfer the cement from big bags and bags to cement silo and cement batchers. Screw Conveyor which have galvanized maintenance covers and special intermediate bearings, also are equipped with central lubrication system. This system is designed to provide operating convenience to our customers and is implemented in all Screw Conveyor as standart.