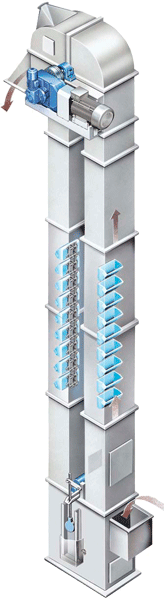

Bucket elevators are designed to move flowing powders or bulk

solids vertically. Bucket elevators use an endless belt or chain and have a series of

buckets attached to it. Bulk material is spread into an inlet hopper. Buckets (or cups) dig

into the material and convey it up and over the head sprocket/pulley, and then throw the

material out a discharge throat.

Bucket elevators are not self-feeding, and are fed at a controlled rate. The buckets are

usually where the chain or belt path is vertical or steeply inclined in a single plane. The

buckets are returned back down to a tail pulley or sprocket at the bottom.

There are four broad classifications of bucket elevators: centrifugal, continuous, positive,

and internal discharge. The most commonly used are the centrifugal and continuous discharge

elevators.

Orthman Conveying Systems' industrial bucket elevators are made in a variety of shapes,

weights and sizes, all utilizing centrifugal buckets or continuous buckets

Continuous bucket elevators are used to handle friable, fragile materials because they minimize product damage or are used to handle light fluffy materials where aeration of the product must be avoided. Continuous bucket elevators have buckets spaced continuously and operate at slower speeds. The continuous bucket placement allows the force of gravity to discharge their load onto the inverted front of the proceeding bucket. The bucket then guides that material into the discharge throat on the descending side of the elevator.